The temperature of the absorbed fluid should not exceed 90 ° C.

ErP : These fans are within the scope of Directive 2009/125 / EC. This law does not apply in the following cases:

- Working in potentially explosive atmospheres (ATEX)

- Operation at high temperatures (fans designed with cooling fan)

- Operation at temperatures below -40°C

- Working in toxic, corrosive or corrosive environments (use of materials such as AISI 304, AISI 316, manganese steels).

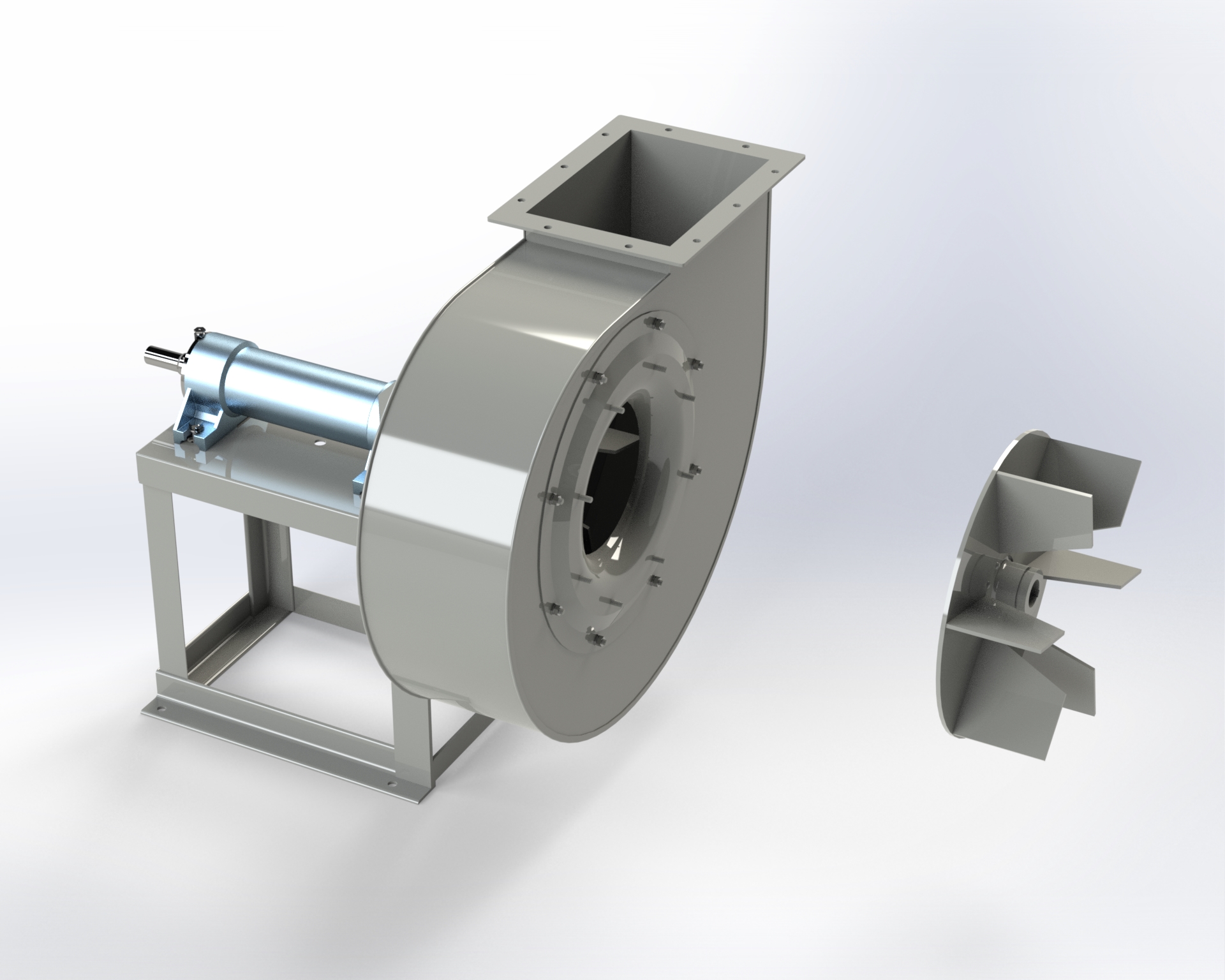

These series are centrifugal backward curved fans and therefore Ntarget = 61 is expected (Reg. UE N.327 / 2011).

Efficiency IE2 motors conforming to IEC 60034-30 are taken into account in ErP calculations.

Please note that these fans are designed to carry material. For this reason, Directive 2009/125/CE applies, but is not subject to the energy efficiency restrictions it imposes and thus the verification of these parameters.

Product Technical Information

| AIR FLOW | 36 – 115 m3/min |

| INPUT PRESSURE | 262 – 336 kg/m2 |

| OUTPUT PRESSURE | 270 – 348 kg/m2 |

| ENGINE BOARD | N/A – N/A poles |

| INSTALLED POWER | N/A KW |

| ROTATION SPEED | 2800 rpm |

| SPEED LIMIT | N/A rpm |

| LIQUID TYPE | Material transfer |

| INLET FLANGE | ⌀286mm |

| OUTLET FLANGE | 355x250mm |

| WEIGHT WITHOUT MOTOR | 106 Kg |

| SE 2 | 1 Kgm2 |

Use : For suction of very dusty air containing various types of material in suspension.

Special open-wing TPALc transport type for conveying filament material, especially used for conveying wool, rags, lint, wadding, carding rooms, wool mills, etc. Made for the textile industry.

– Easy setup

– High energy saving

– Silent

– Made with high quality raw materials

– Long years of use guarantee

– High efficiency