BUILDING FEATURES

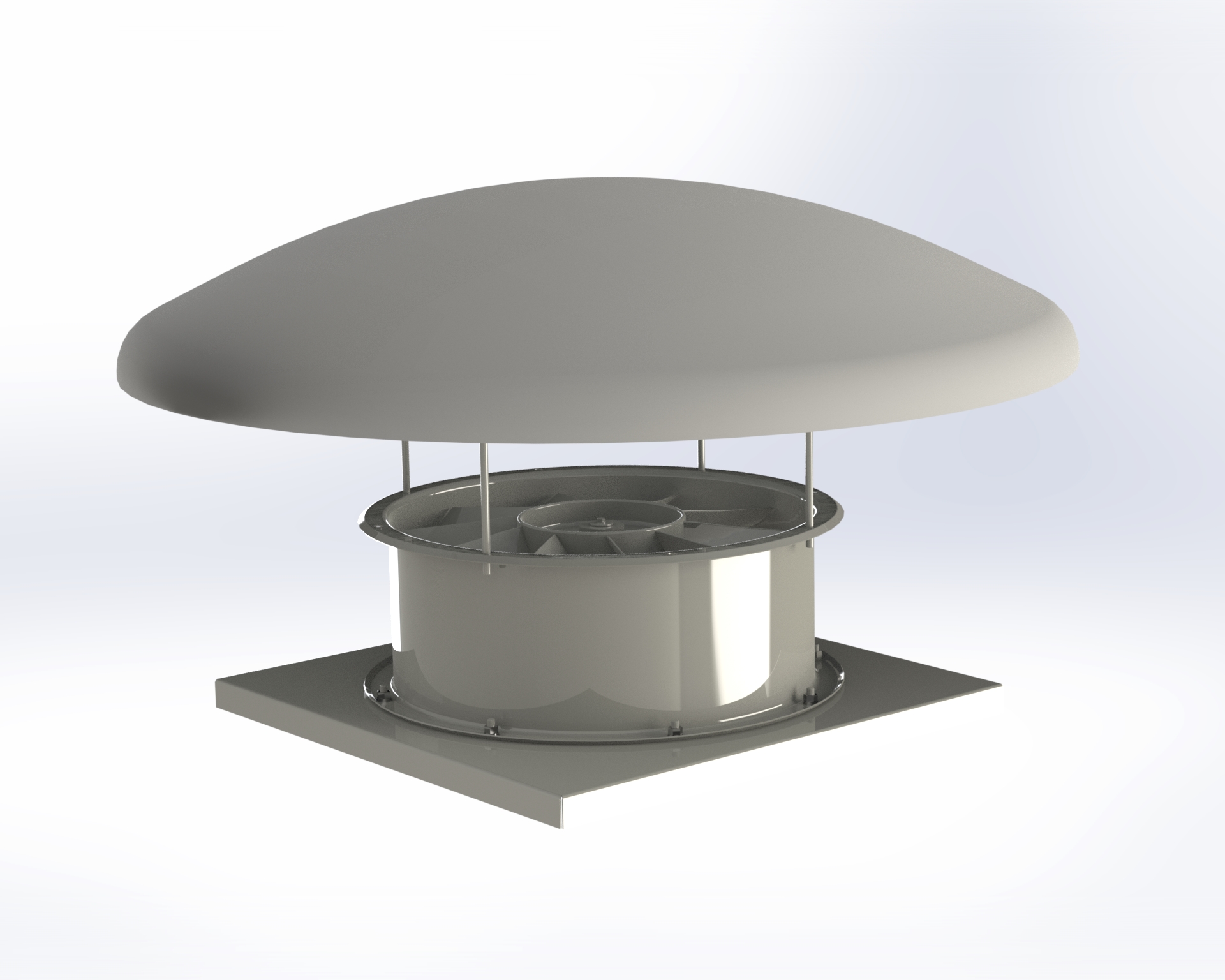

Tower . Exterior structures are flanged pressed steel sheet with double holes for anchoring to the roof or to the end of a pipe, complete with bracket to accommodate the drive motor.

Light alloy (spark proof) die-cast helical rotor, dynamically balanced ring contour vanes, mounted on the drive shaft. Blade angle of rotor from 710 to 1000 when fan is stopped

adjustable. Removable, rain-proof roof made of fiberglass-reinforced plastic (polyester resin). The air direction is from the motor to the rotor (it is always possible to reverse the airflow by reversing the rotation of the motor, removing and reinstalling the rotor, i.e. from rotor to motor).

Custom applications on request. Painting the exterior with acid and rust resistant paint. Spark proof unit with explosion proof motor.

Optional accessories. Anchor base. Shutters that open automatically with the passage of air flow.

ErP : These fans are within the scope of Directive 2009/125 / EC. This law does not apply in the following cases:

- Operation in potentially explosive atmospheres (ATEX)

- Operation at high temperatures (fans designed with cooling fan)

- Operation at temperatures below -40 °C

- Working in toxic, corrosive or corrosive environments (use of materials such as AISI 304, AISI 316, manganese steels).

These series are axial fans and therefore Ntarget = 50 is expected (Reg. UE N.327 / 2011).

Efficiency IE2 motors conforming to IEC 60034-30 are taken into account in ErP calculations.

Product Technical Information

| AIR FLOW | 230 – 350 m3/min |

| INPUT PRESSURE | 8 – 20 kg/m2 |

| OUTPUT PRESSURE | 8 – 20 kg/m2 |

| ENGINE BOARD | 90 L – 6 poles |

| INSTALLED POWER | 1.1 kW |

| ROTATION SPEED | 930rpm |

| SPEED LIMIT | 980 rpm |

| LIQUID TYPE | Clean |

| INLET FLANGE | ⌀800mm |

| OUTLET FLANGE | 800 x N/A mm |

| WEIGHT WITHOUT MOTOR | 60 Kg |

| SE 2 | N/A Kgm2 |

Use : Exhaust towers are suitable for absorbing degraded air flue gases and vapors from the environment. It is very useful in the summer season in environments where air exchange is required for ventilation of the room.

They are also used in the ventilation of workshops, foundries, cement plants, tanneries, joinery and in the chemical, mechanical and metallurgical industries where large volumes of air must be sucked in at low pressure.

– Easy setup

– High energy saving

– Silent

– Made with high quality raw materials

– Long years of use guarantee