The temperature of the sucked liquid should not exceed 80°C without cooling fan and 150°C with cooling fan. For higher temperatures it is necessary to make some changes in the structure of the fan.

ErP : These fans are within the scope of Directive 2009/125 / EC. This law does not apply in the following cases:

- Working in potentially explosive atmospheres (ATEX)

- Operation at high temperatures (fans designed with cooling fan)

- Operation at temperatures below -40°C

- Working in toxic, corrosive or corrosive environments (use of materials such as AISI 304, AISI 316, manganese steels).

These series are centrifugal backward curved fans and therefore Ntarget = 61 is expected (Reg. UE N.327 / 2011).

Efficiency IE2 motors conforming to IEC 60034-30 are taken into account in ErP calculations.

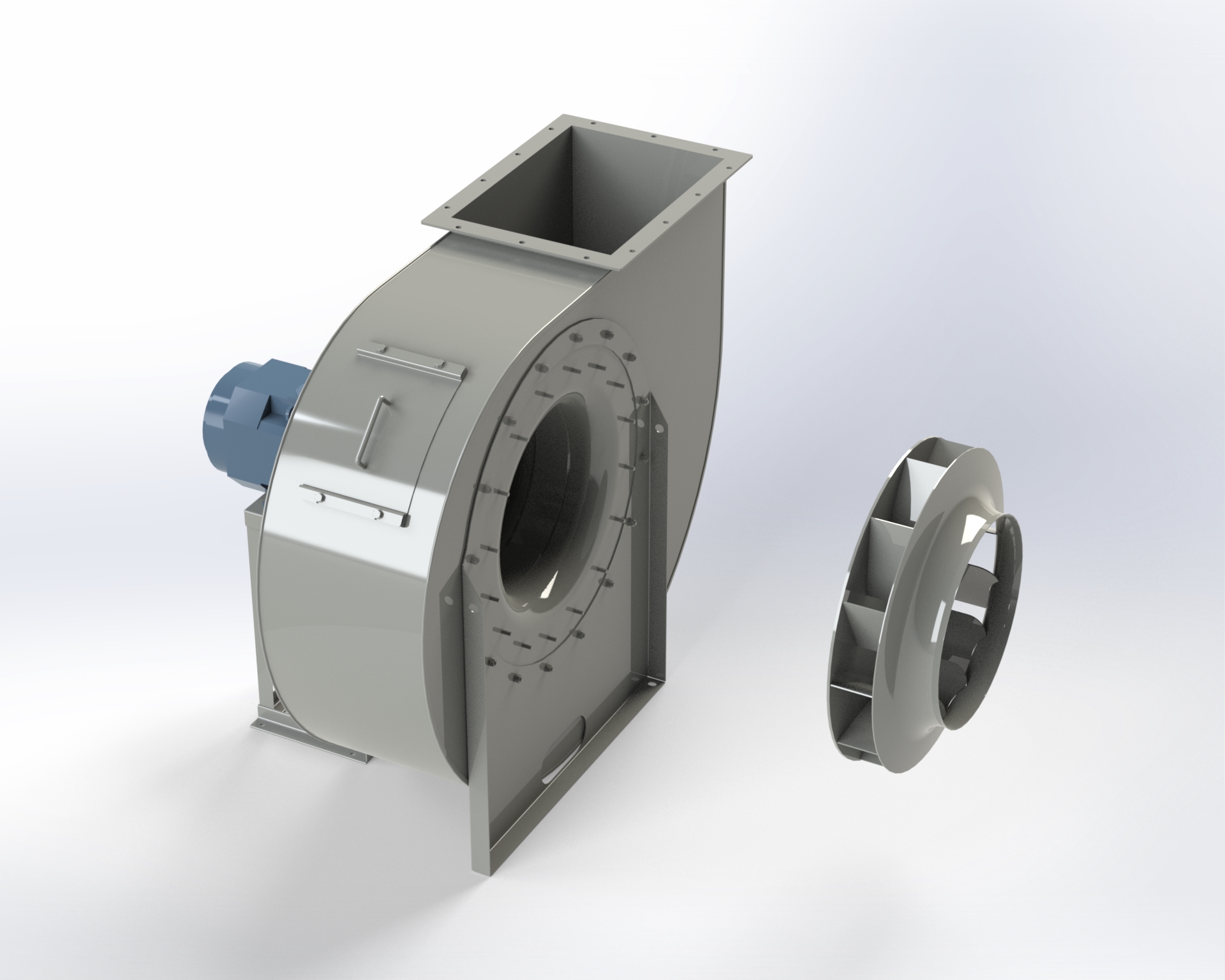

Product Technical Information

| AIR FLOW | 43 – 102 m3/min |

| INPUT PRESSURE | 104 – 124 kg/m2 |

| OUTPUT PRESSURE | 113.5 – 127 kg/m2 |

| ENGINE BOARD | 100 LA – 4 poles |

| INSTALLED POWER | 2.2 kW |

| ROTATION SPEED | 1450 rpm |

| SPEED LIMIT | 1480 rpm |

| LIQUID TYPE | Clean, Dusty, Material transfer. |

| INLET FLANGE | ⌀456mm |

| OUTLET FLANGE | 450x315mm |

| WEIGHT WITHOUT MOTOR | 146 Kg |

| SE 2 | 3.7 Kgm2 |

Use : For absorbing very dusty air containing various types of material in suspension. The main feature of such fans is that high efficiency (resulting from the use of an inverted blade rotor, special profile) is associated with the suction of powdery liquids or those containing granular materials. Also these fans are characterized by a very flat curve of the absorbed power so that the motor is not overloaded when running with open inlets.

They are installed in joinery to transport saw dust and wood shavigs, excluding filamentous material, in mechanical industries to absorb metal chips, pneumatic conveying of cement plants, ceramic plants, mills, feed mills, tanneries, foundries, textile and chemical. It is used in industries where it is necessary to transport harmful air at low and medium pressure, and in all these applications in general.

– Easy setup

– High energy saving

– Silent

– Made with high quality raw materials

– Long years of use guarantee

– High efficiency