BUILDING FEATURES

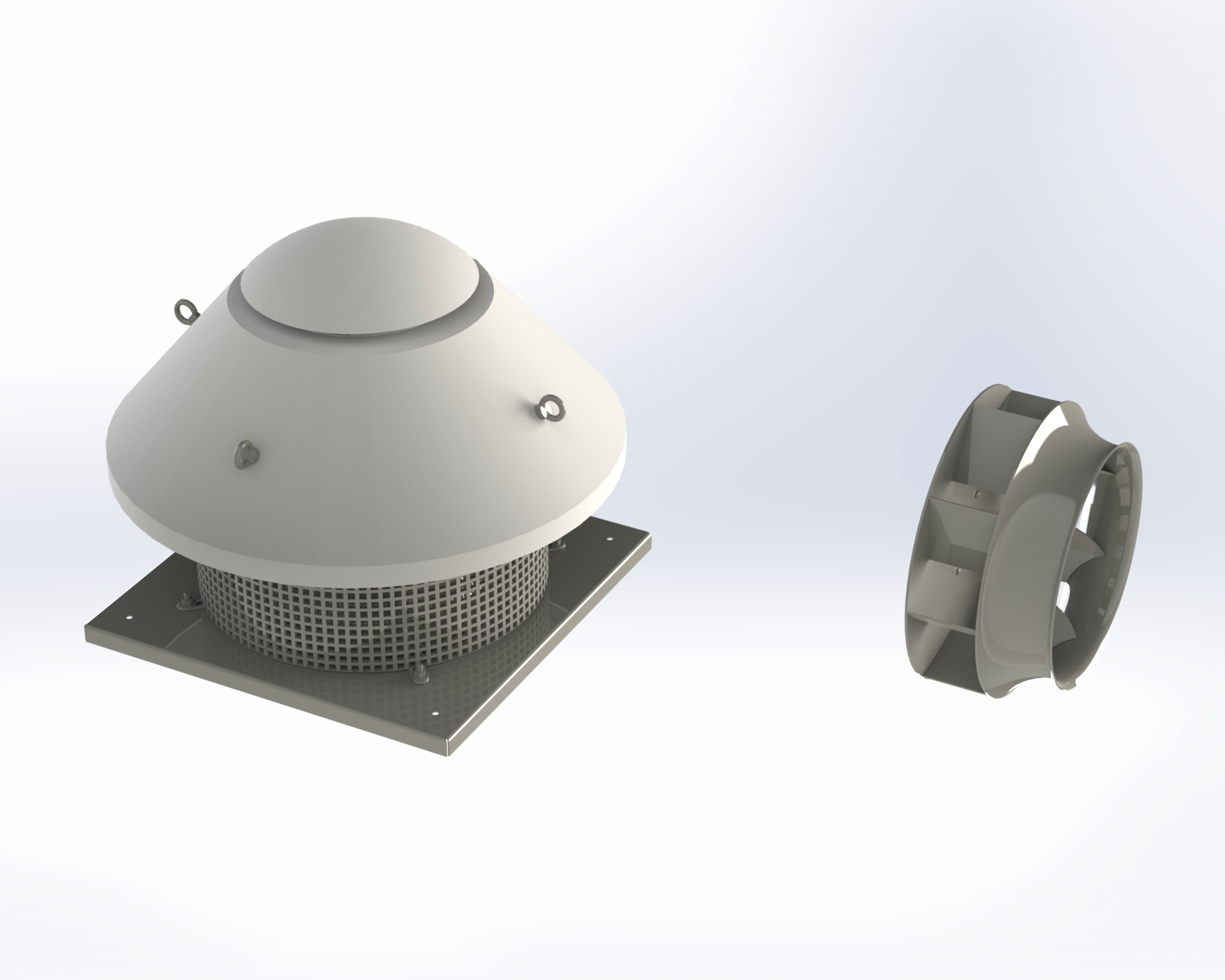

The assembly consists of a high-capacity centrifugal fan impeller, which is statically and dynamically balanced. The centrifugal fan wheel is driven by an electric motor in the form of B5-V1 and supported by a strong accident prevention galvanized mesh. It is mounted on the roof of the building by placing it on a square base and is protected from atmospheric factors with a glass fiber hood.

ErP : These fans are not subject to ErP as they are considered exhaust towers.

Product Technical Information

| AIR FLOW | 63 – 160 m3/min |

| INPUT PRESSURE | 32 – 74 kg/m2 |

| OUTPUT PRESSURE | 32 – 74 kg/m2 |

| ENGINE BOARD | N/A – 4-pole |

| INSTALLED POWER | 2.2 kW |

| ROTATION SPEED | 1400 rpm |

| SPEED LIMIT | 1450 rpm |

| LIQUID TYPE | Clean |

| INLET FLANGE | ⌀500mm |

| OUTLET FLANGE | 500 x N/A mm |

| WEIGHT WITHOUT MOTOR | 55 Kg |

| SE 2 | 2.9 Kgm2 |

Use : Exhaust towers are suitable for absorbing degraded air flue gases and vapors from the environment. It is very useful in the summer season in environments where air exchange is required for ventilation of the room.

They are also used in the ventilation of workshops, foundries, cement plants, tanneries, joinery and in the chemical, mechanical and metallurgical industries where large volumes of air must be sucked in at low pressure.

Minimum operating temperature – 20 ° C, maximum + 80 ° C (+ 150 ° C with cooling fan !!).

– Easy setup

– High energy saving

– Silent

– Made with high quality raw materials

– Long years of use guarantee