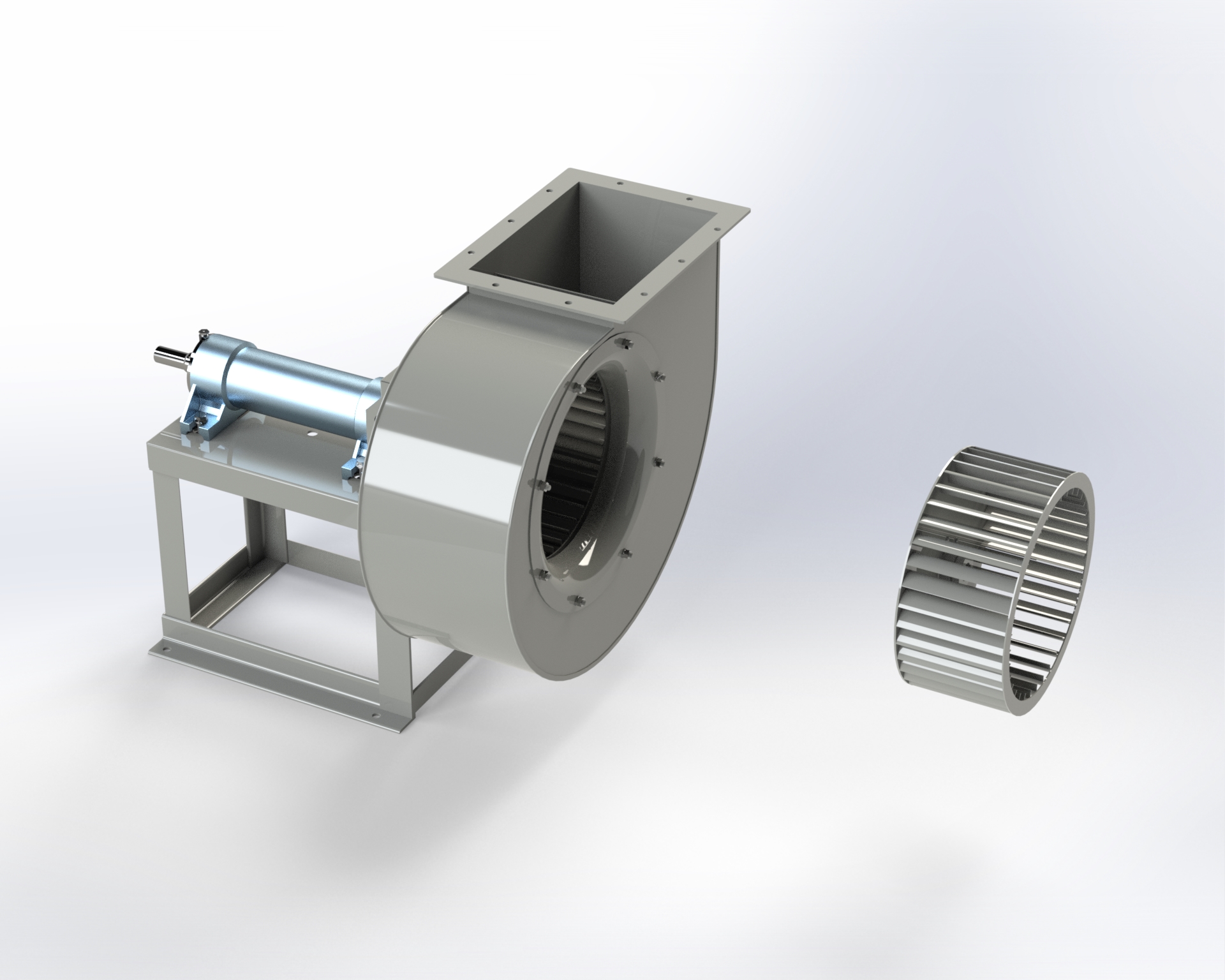

LOW PRESSURE CENTRIFUGAL FAN. FORWARD CURVED bladed propeller. SAFETY BELT.

This series is also used where it is necessary to transport air at a maximum temperature of 90°C at low pressure. For temperatures of the transported fluid from 90°C to higher than 350°C, a small heat-stop fan is threaded on the shaft between the support and the spiral; In addition, the fan is painted with special aluminum paint suitable for high temperatures.

ErP : These fans are within the scope of Directive 2009/125 / EC. This law does not apply in the following cases:

- Operation in potentially explosive atmospheres (ATEX)

- Operation at high temperatures (fans designed with cooling fan)

- Operation at temperatures below -40 °C

- Working in toxic, corrosive or corrosive environments (use of materials such as AISI 304, AISI 316, manganese steels).

These series are centrifugal forward curved fans and therefore Ntarget = 42 is expected (Reg. UE N.327 / 2011).

Efficiency IE2 motors conforming to IEC 60034-30 are taken into account in ErP calculations.

General Notes:

When using Variable Speed Drives, please be aware of possible overheating of the motor due to lower rpm/Hz than recommended by the motor supplier.

Product Technical Information

| AIR FLOW | 24 – 115 m3/min |

| INPUT PRESSURE | 171.5 – 207 kg / m2 |

| OUTPUT PRESSURE | 175 – 211 kg / m2 |

| ENGINE BOARD | N/A – N/A poles |

| INSTALLED POWER | N/A KW |

| ROTATION SPEED | 2900 rpm |

| SPEED LIMIT | 2950rpm |

| FLUID TYPE | Clean, Dusty |

| INLET FLANGE | ⌀ 255mm |

| OUTLET FLANGE | 250 x 180mm |

| WEIGHT WITHOUT MOTOR | 28 Kg |

| SE 2 | 0.18 Kgm 2 |

Use : High output centrifugal fans of this series are suitable for suction of clean or slightly dusty air in facilities in civil and industrial air conditioning.

Specifically for these facilities:

Ventilation : stables, mines. tunnels.

Suction : degraded air, welding fumes, vapors from solvent tanks and spray booths.

Ventilation : storage boxes, hangars.

Cooling : plastic materials, cloths, glass sheets.

Drying : feed, grains, papers, varnishes, wood.

Elimination : fumes and toxic gas.

– High energy saving

– Silent

– Made with high quality raw materials

-Long years of use guarantee

-Easy setup