For temperatures of the conveyed liquid from 90°C to higher than 350°C, a small heat-stop fan is threaded on the shaft between the support and the spiral; In addition, the fan is painted with special aluminum paint suitable for high temperatures.

.

ErP : These fans are within the scope of Directive 2009/125 / EC. This law does not apply in the following cases:

- Working in potentially explosive atmospheres (ATEX)

- Operation at high temperatures (fans designed with cooling fan)

- Operation at temperatures below -40°C

- Working in toxic, corrosive or corrosive environments (use of materials such as AISI 304, AISI 316, manganese steels).

These series are centrifugal forward curved fans and therefore Ntarget = 42 is expected (Reg. UE N.327 / 2011).

Efficiency IE2 motors conforming to IEC 60034-30 are taken into account in ErP calculations.

special rate> In the case of 1.11, please note that Directive 2009/125 / CE applies, but these fans are not subject to the energy efficiency restrictions imposed and thus the verification of these parameters.

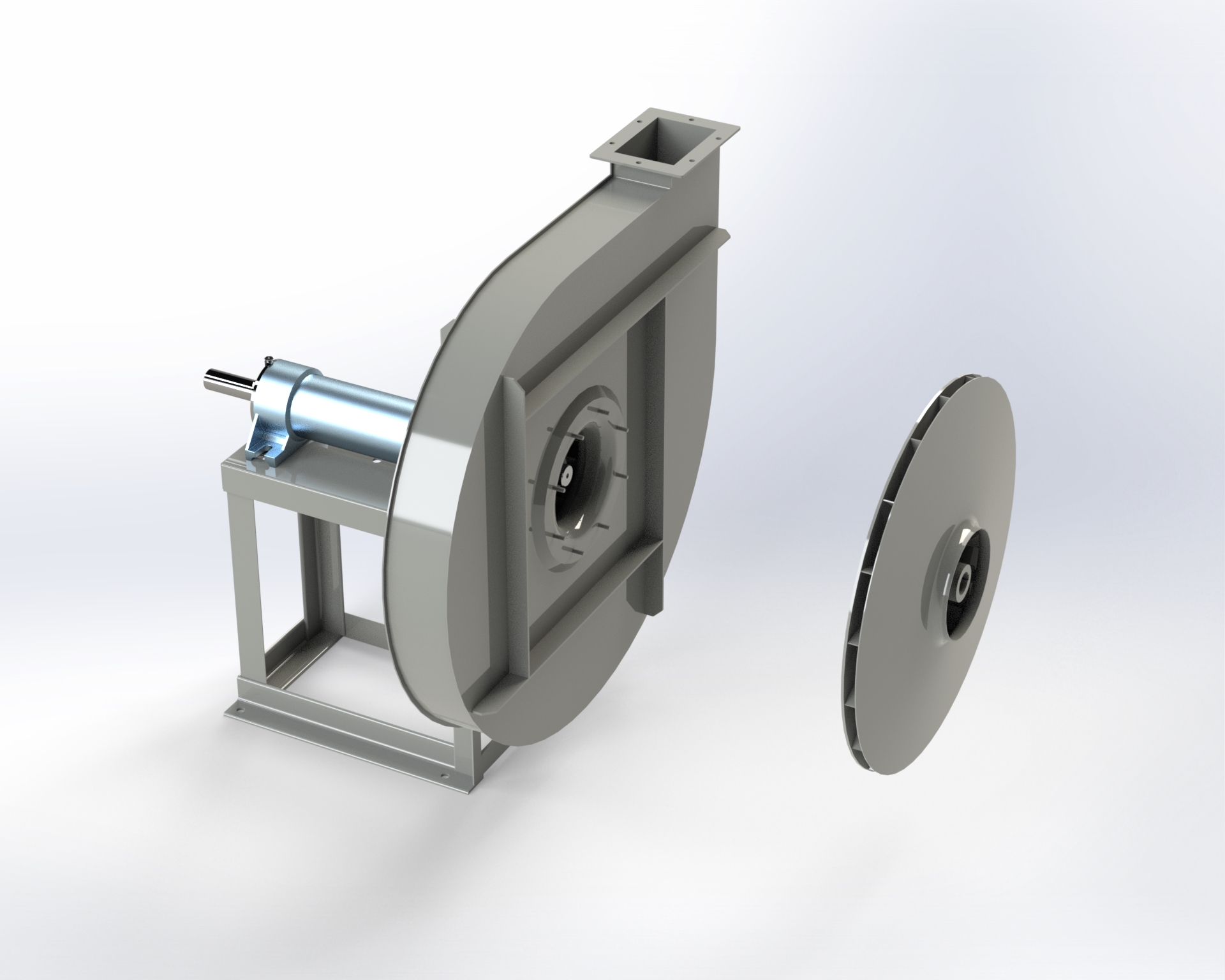

Product Technical Information

| AIR FLOW | 90 – 250 m3/minute |

| INPUT PRESSURE | 926 – 1250 kg/m2 |

| OUTPUT PRESSURE | 1040 – 1470 kg/m2 |

| ENGINE BOARD | N/A – N/A poles |

| INSTALLED POWER | N/A KW |

| ROTATION SPEED | 2950 rpm |

| SPEED LIMIT | 3150 rpm |

| LIQUID TYPE | Clean, Dusty |

| INLET FLANGE | ⌀321mm |

| OUTLET FLANGE | 280x200mm |

| WEIGHT WITHOUT MOTOR | 250 Kg |

| SE 2 | 11 Kgm2 |

Use :

Fans of this series are particularly suitable for pneumatic conveying of small capacities in cement plants, air supply of cupolas, foundries and oil burners, mills, “pasta” factories, chemical, metallurgical and iron industries. medium and high pressures are required, also suitable for extracting very dusty air.

– Easy setup

– High energy saving

– Silent

– Made with high quality raw materials

– Long years of use guarantee